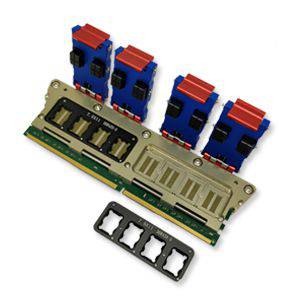

In the industry of lithium battery pack automatic production line process. we all know that the final assembly of lithium battery into finished products and warehousing requires a lot of process flow, from the beginning of loading, cell sorting and assembly. PCM welding, semi-finished product assembly, aging test, pack test (including: protection board test, finished product test), pack packaging, etc. The high current spring micro needle module (blade block) newly developed by KZT kaizhitong microelectronics is mainly used in the protection board test and finished product test of lithium battery pack production line.

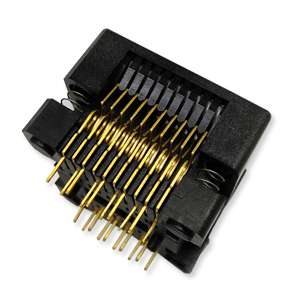

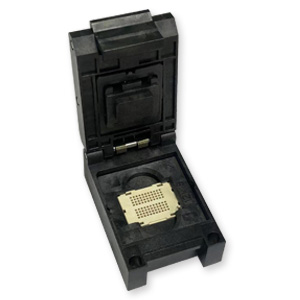

In the test of lithium battery pack automatic line, due to the characteristics of the product, the lithium battery test must have a large current; and before the lithium battery is offline, the full performance test of the product (including: charge and discharge over-current protection test, battery voltage, battery resistance, battery cell voltage, withstand voltage test, etc.); but at present, most of the lithium battery pack production line manufacturers in the market still It is using the traditional connector male and female seat to test, but such a traditional fixture can not meet the test requirements, it is easy to cause product indentation, and the efficiency is very low, the service life is short, about 1000 times of testing will be scrapped, and the more times it is used, the more likely to cause false test phenomenon, so for the above lithium battery, power supply and other products testing As required, KZT kaizhitong microelectronics has recently developed a large current shrapnel micro needle module (blade block).

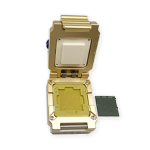

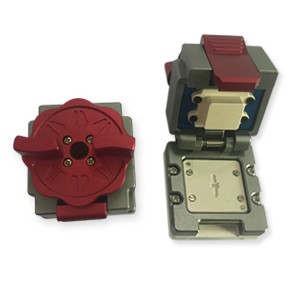

KZT kaizhitong microelectronics new research and development of high current spring micro needle module (blade Block) adopts modular combination, can cope with pitch ≤ 0.15mm, can pass the maximum constant current up to 50a, and will not damage the lithium battery connector, and the test equipment life is longer, which makes the factory improve the test speed, at the same time, the lithium battery finished product test will be very accurate, and will let the lithium battery yield to a higher level, meet the requirements of lithium battery pack production line from all aspects Test requirements of lattice.

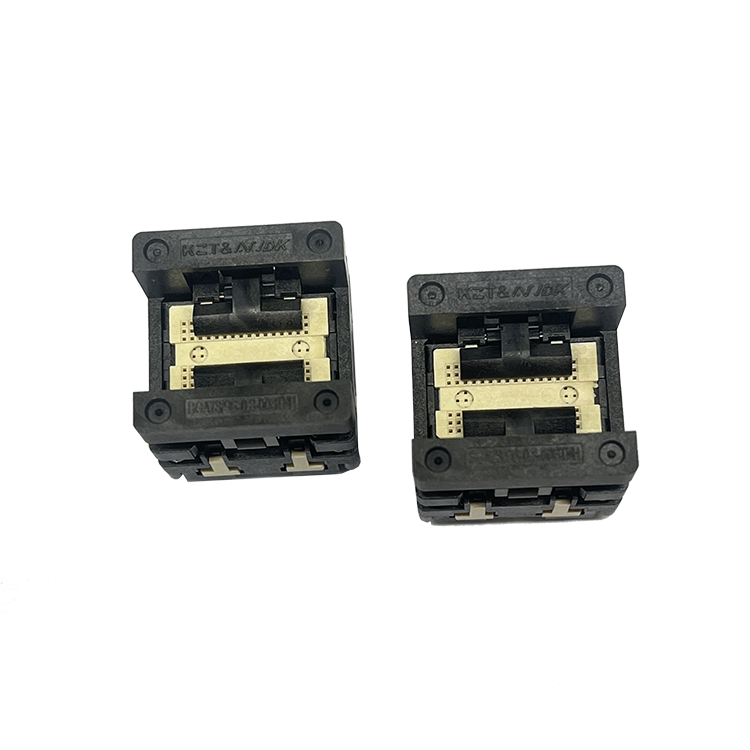

In order to verify the products of the high current spring micro needle module (blade block) newly developed by KZT kaizhitong Microelectronics Co., Ltd Block) the first mock exam was compared with the product, and the same module was placed under 500 times microscope before and after 20 times. Compared with the test, the connector can basically see no trace.

58

58